The Role of 3d Printing in Building with Composites

The innovative technology of 3D printing has revolutionized various industries, providing endless possibilities for creating complex and customized structures. When it comes to building with composites, 3D printing offers a range of advantages that traditional manufacturing methods simply cannot match. From increased design flexibility to enhanced structural performance, the integration of 3D printing in composite construction is reshaping the way we approach building projects.

Enhanced Design Flexibility

One of the key benefits of using 3D printing in building with composites is the unparalleled design flexibility it offers. Traditional manufacturing processes often come with limitations in terms of geometric complexity and customization. With 3D printing, designers have the freedom to create intricate and organic shapes that were previously unattainable. This flexibility enables architects and engineers to push the boundaries of conventional design, resulting in structures that are both aesthetically striking and highly functional.

Improved Structural Performance

Incorporating 3D printing technology in composite construction can significantly enhance the structural performance of the final product. By precisely controlling the deposition of materials layer by layer, 3D printing allows for the creation of composite structures with optimized strength-to-weight ratios. This level of customization enables designers to tailor the mechanical properties of the composites to meet specific performance requirements, resulting in lighter, stronger, and more durable components.

Cost-Effective Prototyping

Another advantage of using 3D printing in building with composites is its cost-effective prototyping capabilities. Traditional prototyping methods can be time-consuming and expensive, especially when dealing with complex composite structures. 3D printing streamlines the prototyping process by eliminating the need for specialized tooling and reducing material waste. This allows designers to quickly iterate on their designs, test different configurations, and make adjustments on the fly, ultimately saving both time and money in the development phase.

Sustainable Construction Practices

As sustainability becomes an increasingly important consideration in the construction industry, the use of 3D printing in building with composites offers a more environmentally friendly alternative to traditional manufacturing methods. By utilizing additive manufacturing techniques, 3D printing reduces material waste and energy consumption, making it a more sustainable option for producing composite structures. Additionally, the ability to recycle and reuse materials in the 3D printing process further contributes to a more eco-friendly approach to construction.

Complex Assembly Simplified

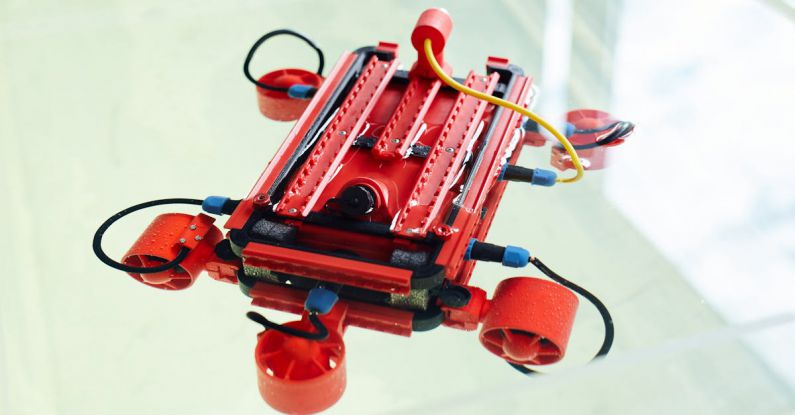

One of the challenges often faced in composite construction is the complexity of assembly, especially when dealing with intricate shapes and configurations. 3D printing addresses this issue by enabling the fabrication of complex components as a single piece, eliminating the need for time-consuming and labor-intensive assembly processes. This not only streamlines production but also reduces the risk of errors and inconsistencies that can arise during traditional assembly methods, ensuring a higher level of precision and quality in the final product.

Future Outlook and Potential Applications

Looking ahead, the integration of 3D printing in building with composites is poised to continue shaping the future of construction. From architectural facades to structural elements, the possibilities for utilizing 3D printing technology in composite construction are vast. As the technology advances and becomes more accessible, we can expect to see even greater innovation in the design and construction of composite structures, pushing the boundaries of what is possible in the built environment.

In conclusion, the role of 3D printing in building with composites is transforming the way we approach construction projects, offering unparalleled design flexibility, improved structural performance, cost-effective prototyping, sustainable practices, and simplified assembly processes. With its ability to push the boundaries of traditional manufacturing methods and unlock new possibilities in composite construction, 3D printing is paving the way for a more efficient, sustainable, and innovative built environment.